info@unitech-india.net - GST NO. : 27AADCD6209Q1Z8

- Send Email

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | UniTech |

| Application | Screen Printing On Various Materials |

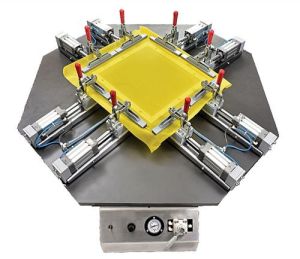

| Type | Screen Printing Press |

| Click to view more | |

Product Details

EASIPRINT M2-Series is a vertical lift two post pillar screen printing press. It is a semi auto flat motorized screen printing machine that offers superior print performance with zero registration issues. The machine delivers output of 800 impressions per hour.

EASIPRINT M2 series screen printing machine is suitable for shorter print runs due to its simple & fast loading unloading mechanism of screen Printing frames. The design of the machine ensures :

-

Safety of the operator

-

Easy to service

-

Effortless to operate

-

Occupies lesser production space

EASIPRINT flat motorized screen printing machine has self diagnostic closed loop system which continuously monitors its critical parts & any fault will be exactly identified on the LED panel to drastically reduce breakdown time.

Construction

-

Less space required

-

Screen runs vertically to keep ink on the screen so it does not flow

-

Easy for squeegee, coater & screen replacement as well as screen cleaning

Vacuum System

-

Motorized squeegee / Flood pressure adjustment

-

Heavy-gauge stainless steel vacuum bed top

-

Bed movement for registration

-

Motorized Peel off system

Control Panel

-

Easy to navigate with programming and prompts in plain language

-

Digital microprocessor with self-diagnostics

-

Flood /non-flood setting allows screens to be flooded or left un flooded after each print cycle

-

Hands-free single-cycle printing and for vacuum control of hard-to-feed substrates

-

Cycle interruption with foot start switch

-

Multiple print capability

Print Carriage

-

Adjustable, tool-free front and rear sensors for squeegee stroke length on adjustment

-

Shock absorber to eliminate the shock from printing movement

-

Motorized squeegee / flood pressure adjustment

-

Bed movement for registration

-

Adjustable peel off height & speed of peel-off

-

Safety plate and emergency stop push button for safety operation

Warranty and support

-

One-year warranty on manufacturing defects

-

Microprocessor self diagnostic system on each machine

Technical Specification

| Print Size | mm | 600 x 750 | 600 x 1200 | 610 x 1520 |

| Print Size | inch | 24 x 30 | 24 x 48 | 24 x 60 |

| Sheet Size Max | mm | 680 x 830 | 680 x 1290 | 680 x 1600 |

| Sheet Size Max | inch | 27 x 33 | 27 x 51 | 27 x 63 |

| Frame Size Max | mm | 910 x 1160 | 910 x 1620 | 910 x 1900 |

| Frame Size Max | inch | 36 x 46 | 36 x 64 | 36 x 76 |

| Size of Vacuum Area | mm | 630 x 780 | 630 x 1240 | 630 x 1540 |

| Size of Vacuum Area | inch | 25 x 31 | 25 x 49 | 25 x 61 |

| Max. Substrate Thickness | mm | 50 | 50 | 50 |

| Max. Substrate Thickness | inch | 2 | 2 | 2 |

| Table Fine Adjustment (Y-Y-X) | mm | ±10 | ±10 | ±10 |

| Table Fine Adjustment (Y-Y-X) | inch | 0.3 | 0.3 | 0.3 |

| Squeegee Speed | mm/sec | — | — | — |

| Outer Dimensions (W/L/H) | mm | 1190 x 1300 x 1900 | 1304 x 1880 x 1855 | 1304 x 1880 x 1855 |

| Outer Dimensions (W/L/H) | inch | 47 x 52 x 76 | 50 x 72 x 70 | 50 x 72 x 70 |

| Weight | Kg | 950 | 1050 | 1250 |

| Maximum Speed | Cycle./h | 700 | 700 | 700 |

| Control Panel | — | With Self Diagnostics System | With Self Diagnostics System | With Self Diagnostics System |

Installation Requirements

| Power Supply | — | 3 Phase | 3 Phase | 3 Phase |

| Circuit Connection | — | 4 Pole MCB 25 Amp. | 4 Pole MCB 25 Amp. | 4 Pole MCB 25 Amp. |

| Working Space Requirement | — | 94 x 104 x 76 | 100 x 140 x 70 | 102 x 180 x 73 |

| Air Consumption | l/min | — | — | — |

| Air Compressor | Hp | 1 Hp, 8 bar | 1 Hp, 8 bar | 1 Hp, 8 bar |

| Turbine Blower | Hp | 1 Hp | 1.5 Hp | 2 Hp |